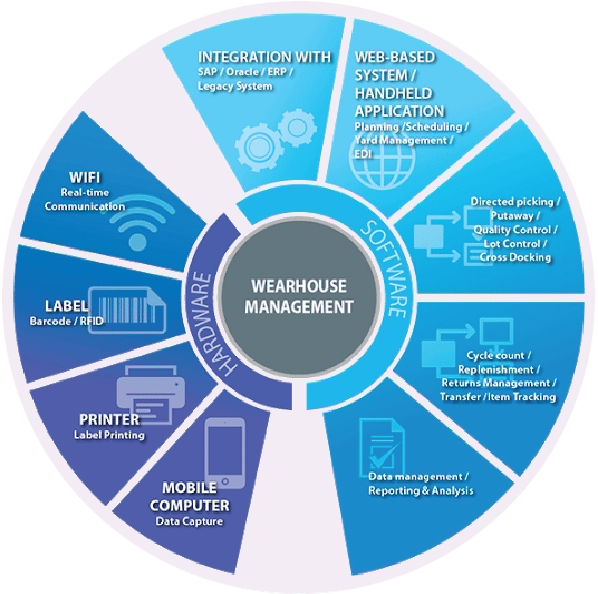

Warehouse Management System

Reduce Labor costs, Reduce Turnaround Time, Quality Improvement

Automated Picking Tools

Pick-to-light: improves picking by making it faster, improving labor allocation and reducing human error

Automated storage and retrieval system

ASRS: automatically placing and retrieving loads from defined storage locations

Smart Warehouse Solutions

IoT ImplementationSensors in the warehouse

can monitor temperature, moisture, and other conditions.

Automated inventory control platforms

requisite use of asset and inventory tags, these platforms allow you to automate stock counting, with data synthesized quickly for real-time, accurate reporting that can be accessed remotely such as RFID

AI Picking Ware house Optimization

Use A.I./M.L. to increase operations productivity, enable scale & reduce costs in warehousing

Location Tracking System

Automatic Identification and Data Capture (AIDC) , Asset Tracking Barcode, RFID, GPS

Automated Guided Vehicles

AGV help to transport materials, suppliers and inventory Within warehouse facilities. AGVs are used in operation to Replace manually driven forklifts or pickcarts

Warehouse Automation Systems

Automated Storage and Retrieval System

ASRS: automatically placing and retrieving loads from defined storage locations

Automatic Guided Vehicles (AGVs)

lurking & lifting AGV specially designed according To customer requirement for production lines and warehouses.

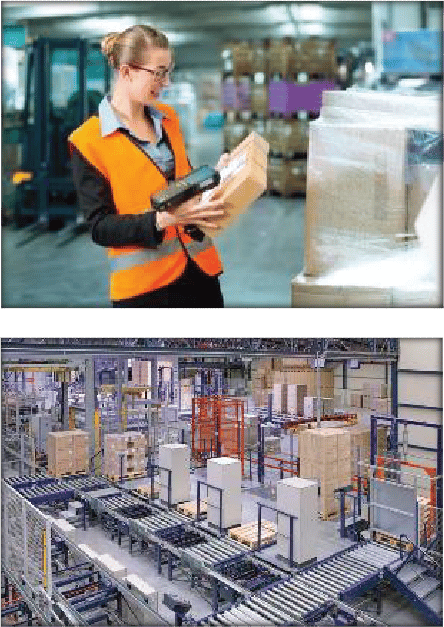

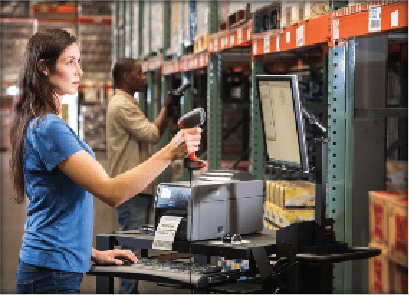

Barcode labels and scanning

Warehouses save dramatic amounts of man hours by automating these documentation processes with barcode labels, rack labels, warehouse signs, and the hardware necessary to read these signs and labels.

Inventory Automation

With over 20 years in the business, our experts can provide you with recommendations for the right scanning and mobile computing devices, barcode label printers, and software to create a solution that will put an end to errors in all parts of the workflow process including data entry, picking, packing and shipping.

Automated order picking

Automated warehouse picking is a collaborative effort. The implementation of robotic or semi-robotic technologies that enhance the work of human pickers.

Automated Sortation System

ASRS sorting equipment and software are the components for accurate and timely product distribution