HUAWEI SMART PORT INTRODUCTION

HUAWEI SMART PORT INTRODUCTION

Port Development Stages

Smart port construction is an effective method to accelerate transformation and upgrade, enable innovations, and build first-class ports with sustainable development — this has become an industry consensus.

Conventional ports

- Movement and storage of sea

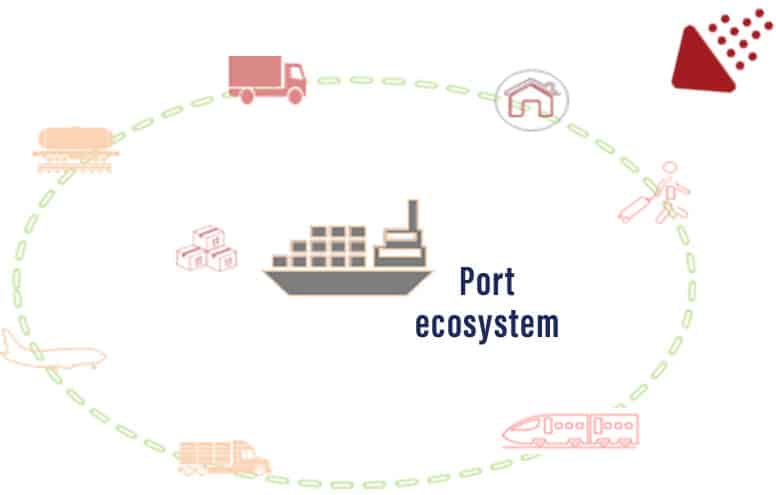

Smart ports

- Refined and agile production.

- Highly ICT-based and networked.

- Provide flexible services to meet personalized requirements.

- Environment protection and carbon emission reduction.

- Port ecosystem; port-city integration.

- Sustainable development.

Modern ports

- Evolve toward trade and logistics centers.

- Provide integrated services such as goods distribution and trade information services.

- Integrate railway and roadway freight resources to provide door-to-door services.

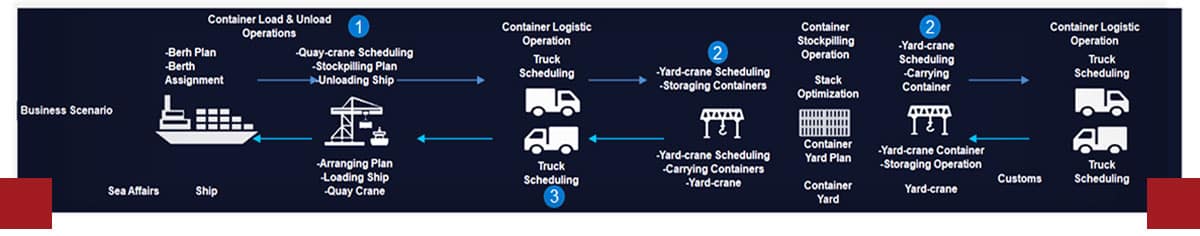

Focuses on Port Business Processes to Solve Customer Pain Points

Tough operating Environment, Difficult Recruitment and High Labor Cost

- Risky work: 30 meter high cabin,no eating or drinking for several hours;noise and vibration.

- Occupational diseases: long-hour head-down work, easy to get cervical spondylosis, etc., retire before 45-years-old.

Efficiency Improvement = Revenue Improvement

- Transport pressure: It is urgent to deal with the challenges brought by large-scale ships and improve operational efficiency.

- Operation collaboration: Smart perception and collaborative operation of various production factors in ports urgently need to form a smart operation flow.

1.Port Brain Intelligent

2.The “Eyes" of full-factor perception

3."Hands" changed from manual to automatic quay bridge & yard bridge container operation automation

4.Autonomous Driving of Container Trucks in Terminals

- Automation of "Legs"

HUAWEI DIGITAL PLATFORM - IOC

Visible, Manageable, and Controllable

Comprehensive service situation

Ship indicator

Container indicator

Vehicle indicator

Performance indicator

Auxiliary indicators

Key indicator forecast

Throughput

Resource

Equipment maintenance

Personnel-related

Collaborative/Emergency command

On-site mgmt

Event mgmt

Emergency mgmt

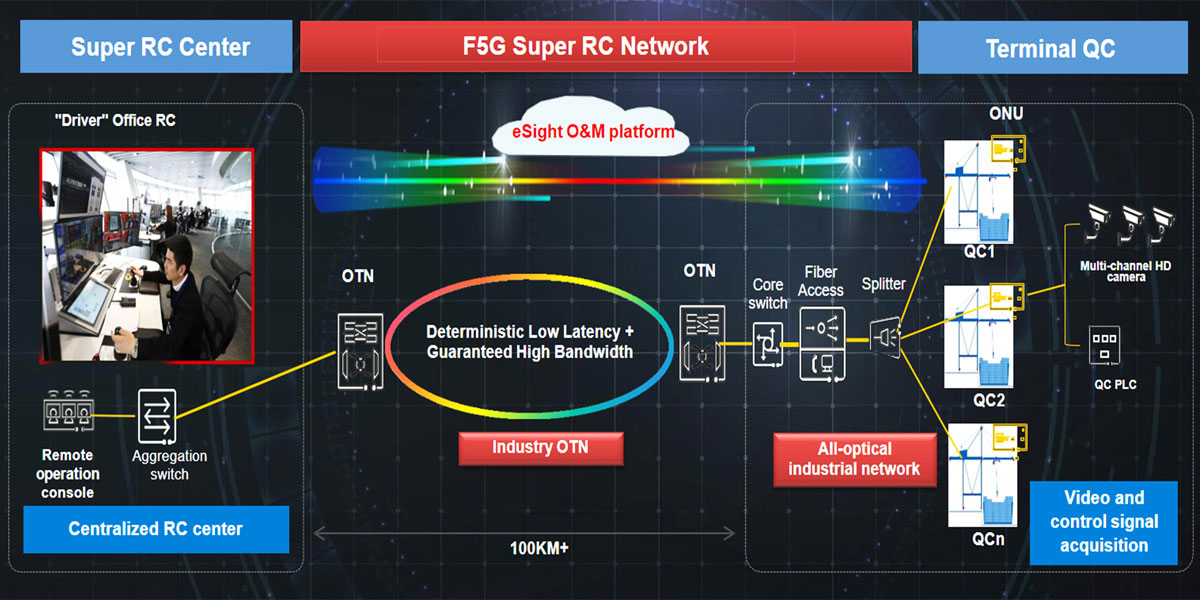

F5G Remote Control Solution System Components

- F5G provides TB-level ultra-large capacity, 100 km ultra-long distance, 1ms deterministic latency, and zero jitter for video and control signals.

- High reliability and protection of industrial-grade ONUs, wide temperature range from 40°C to 70°C, 6 kV surge protection.

- IP-free ONU management, camera/PLC plug-and-play.

PORT-WIDE AI CAPABILITY SUPPORT

Accurate identification of people, vehicles, and pyrotechnics

1. Pyrotechnic Detection

- The camera automatically identifies the smoke before the fire and locates the area where the smoke occurs.

- Real-time identification of regional flames and timely alarms

2. Rate limit Analysis

- Monitor the foreign cartoon road, observe the driving speed of the vehicle and immediately send an alarm if the vehicle is overspeed

Delimit speed monitoring area

Mark the direction of travel of the external truck

Detect Vehicles

Analyze vehicle travel speed

Reporting Alarms

3. Retrograde Detection

- Cameras at key checkpoints are used to capture moving vehicles, identify vehicles that are moving in reverse direction and generate alarms.

Delineation of inspection lines on roads inside the terminal

Detect retrograde vehicles

An alarm event is generated after a vehicle is detected in a reverse direction.

4. Driver get off

- Monitor the east-west and north-south channels of the entire yard, and report the personnel who get off the train in time.

Demarcate the site monitoring area.

Detect Vehicles

Test personnel get off the vehicle

Tracking People's Walk Tracks

5. Track Generation

- Obtains the time points and license plate information of vehicles under cameras at each point, and then generates vehicle tracks in the entire terminal scenario.

Detects vehicle cable crossing and moves the PTZ dome camera to the preset position in advance.

Obtain video streams from PTZ dome cameras and recognize license plates.

6. Personnel detection

- Cameras automatically identify intrusions at perimeters and gates.

- Alarm generation time, display, and archive when an exception occurs.

7. Wearing Security Identification

- Pedestrian identification in high-point scenarios

- Focusing and zooming in to obtain object details

- Video analysis algorithms are used to analyze wear and behavior characteristics of personnel.

- Safety wear & personnel review

8. Congestion Analysis

- Analyze the number of external trucks at intersections in real time and report the queuing status.

- When congestion occurs, alarms are generated in a timely manner to remind the personnel to coordinate.

Demarcate the intersection

monitoring area

monitoring area

Mark the direction of travel of the external trucks

Detect Vehicles

Analyze vehicle travel speed

Analyze vehicle congestion

9. Inspection of personnel inside the refrigerator

- Detects whether personnel enter the freezer area and generates alarms in real time