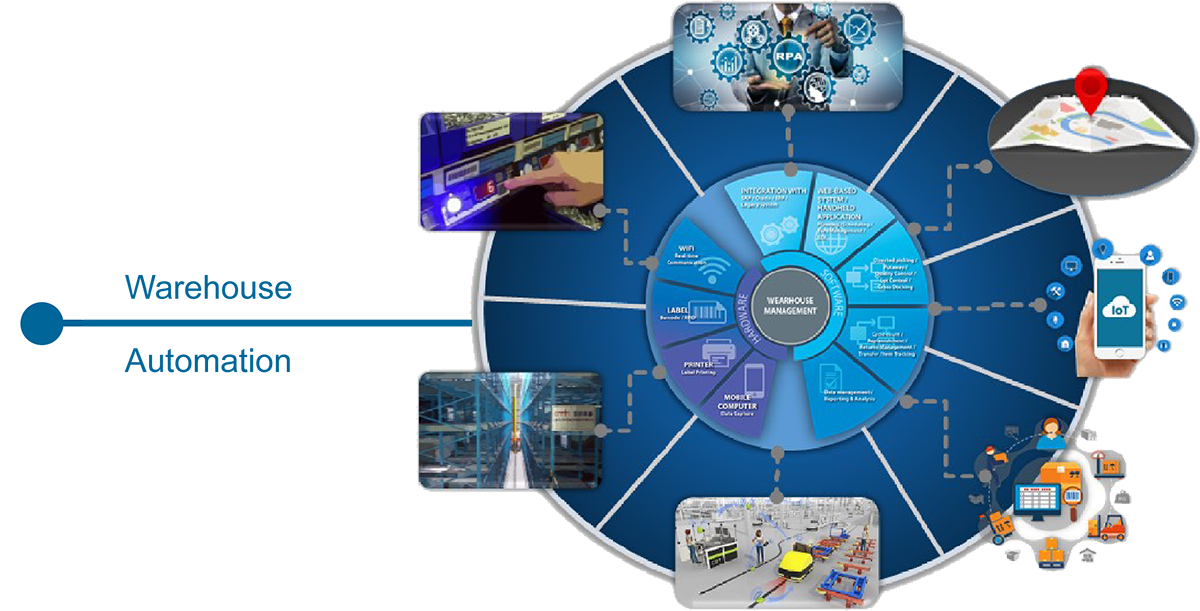

- Warehouse Management System (WM3, Infor)

- Picking System

- Pick-to-Light,

- Voice Recognition

- Optimize Picking

- Automatic Storage and Retrieval System (ASRS)

- Automatic Guided Vehicle (AGV)

- Inventory Management System

- IoT (Internet of Thing)

- Location Tracking System

- Robotic Process Automation (RPA)

Industries Applied Automated Order Picking Systems in Production

- Automotive

- Building products

- E-commerce

- Food and beverage

- Manufacturing

- Medical equipment

- Pharmaceutical

- Retail

- Transportation

The benefits of automated picking systems

- Efficient and effective solution to order fulfilment.

- Picking processes are more efficient leading to reduced labor costs.

- Picking using barcode scanners increases accuracy and leads to more accurate order fulfilment.

- Integrate with Warehouse Management System

- Integration with your business, accounts or ecommerce system

- Accurate live inventory management.

- Eliminates picking labor and reduces the risk of repetitive manual handling

- Flexible and compact designs that can fit into existing footprints

- Improved traceability and 100% order accuracy

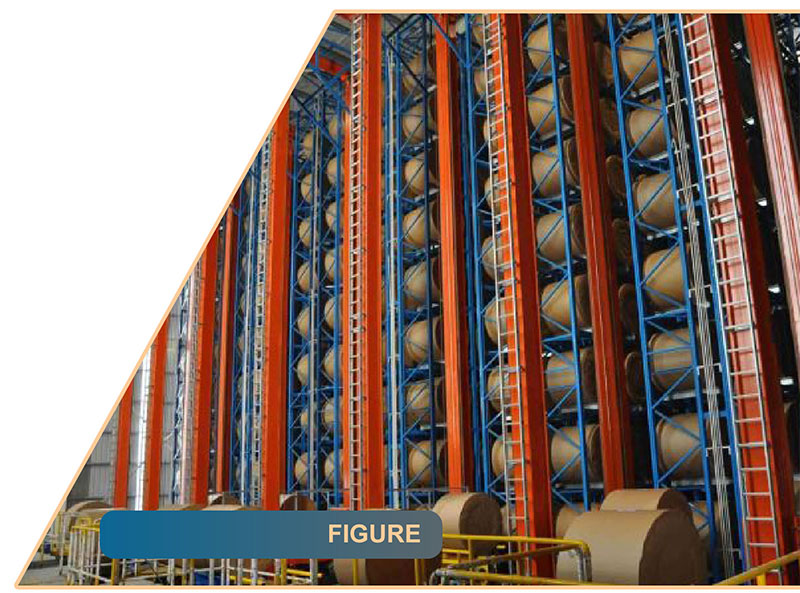

Figure

- Figure : Stacker crane is designed for the Automated Storage & Retrieval Systems of materials

AS/RS

- The AS/RS includes stacker crane, conveyors, picking station, electric control, WMS and racking system.

- It is widely know as computer control system that working in very narrow aisle with high efficiency and fully automatic.

Features & Benefit

- Best use of warehouse

- Fully automatic

- Heavy load capacity

- Silent